Overview:

With the trend of lighter, thinner and

smaller product development, FPC is becoming a well-developed alternative of

the PCB in some product applications.

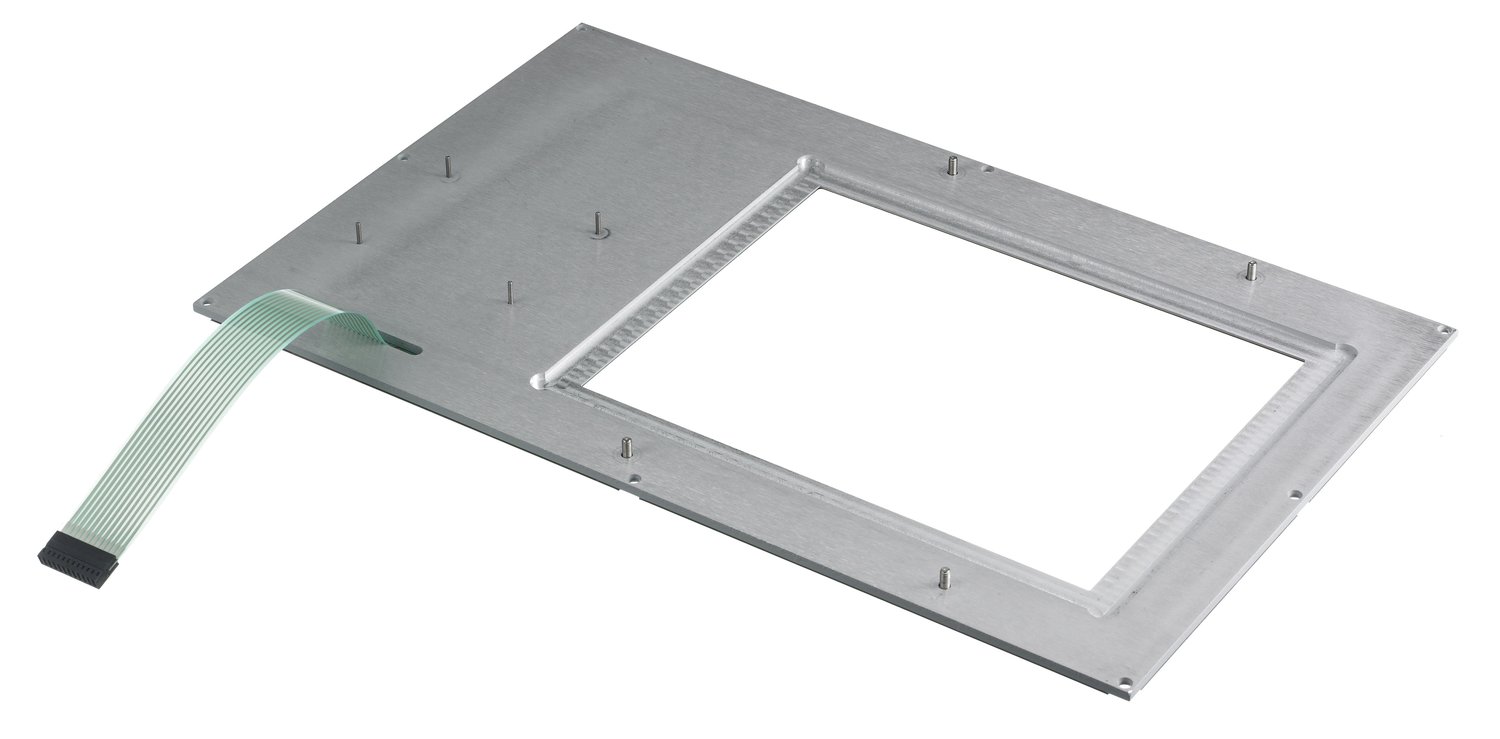

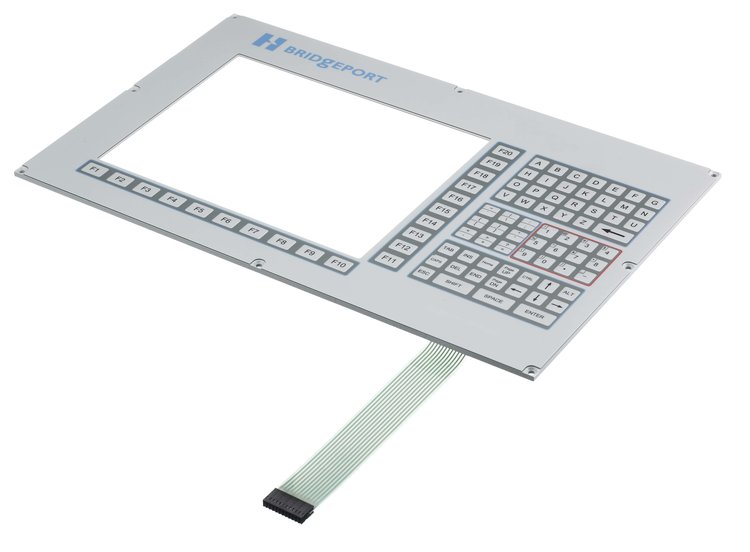

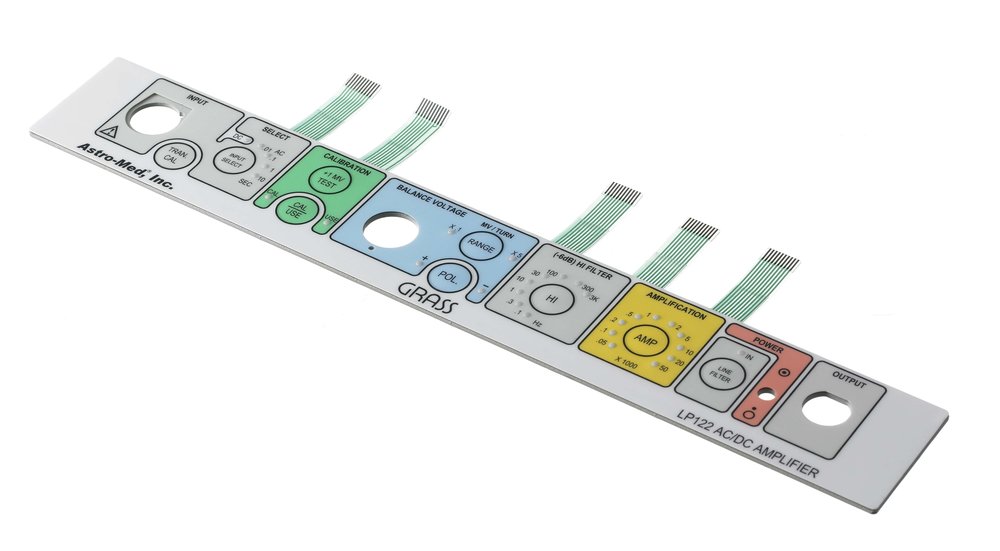

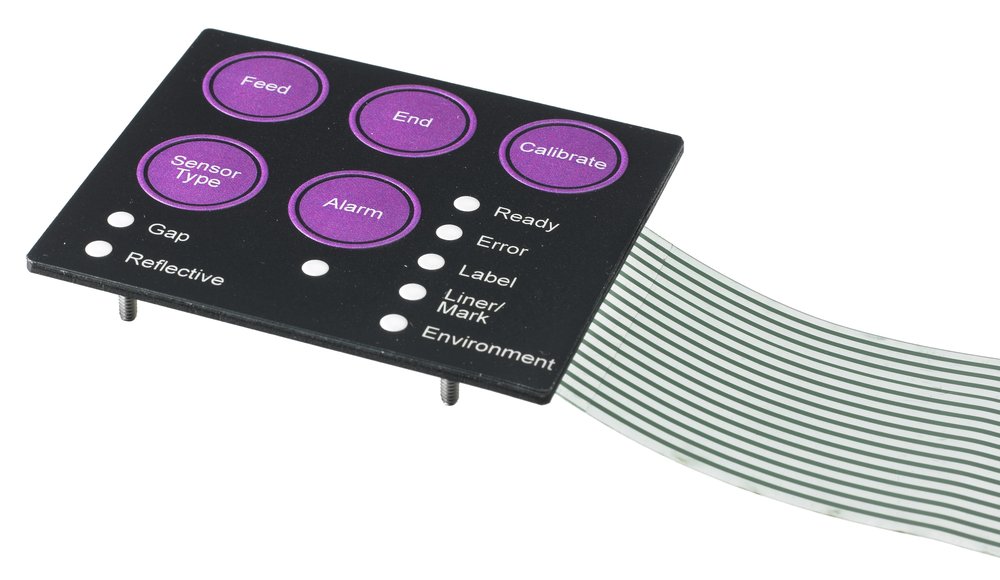

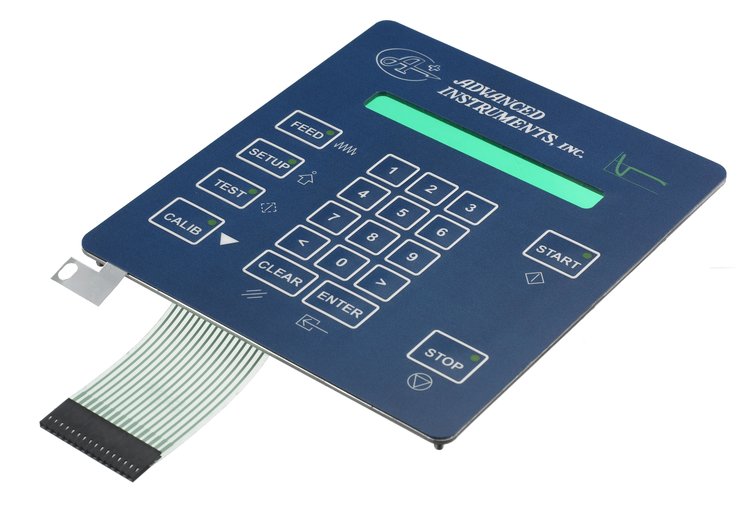

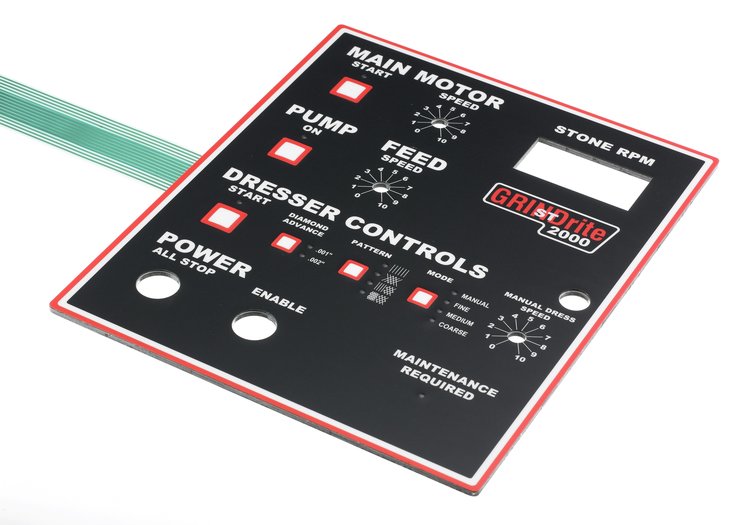

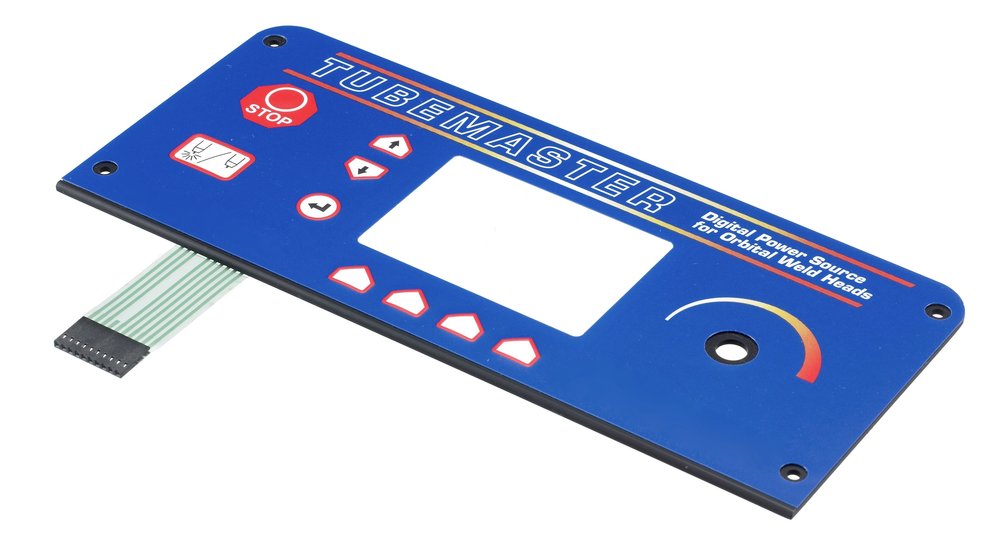

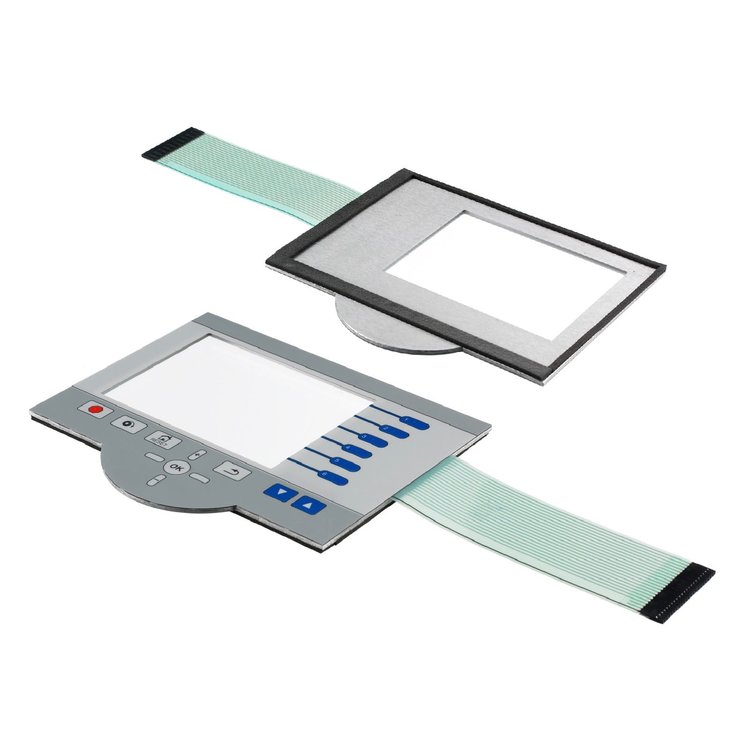

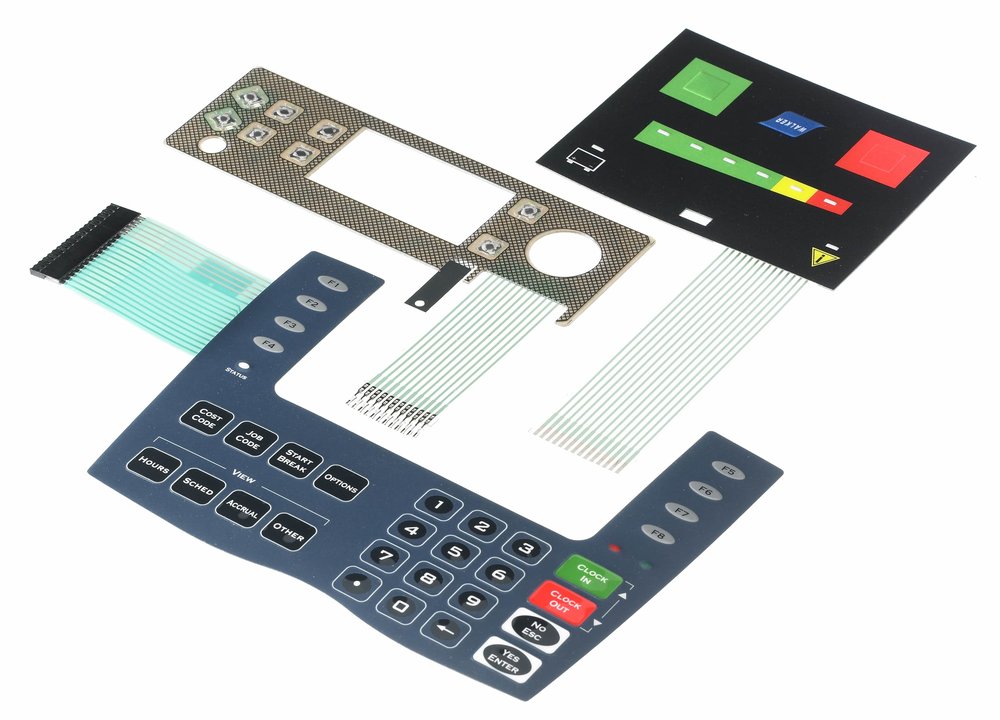

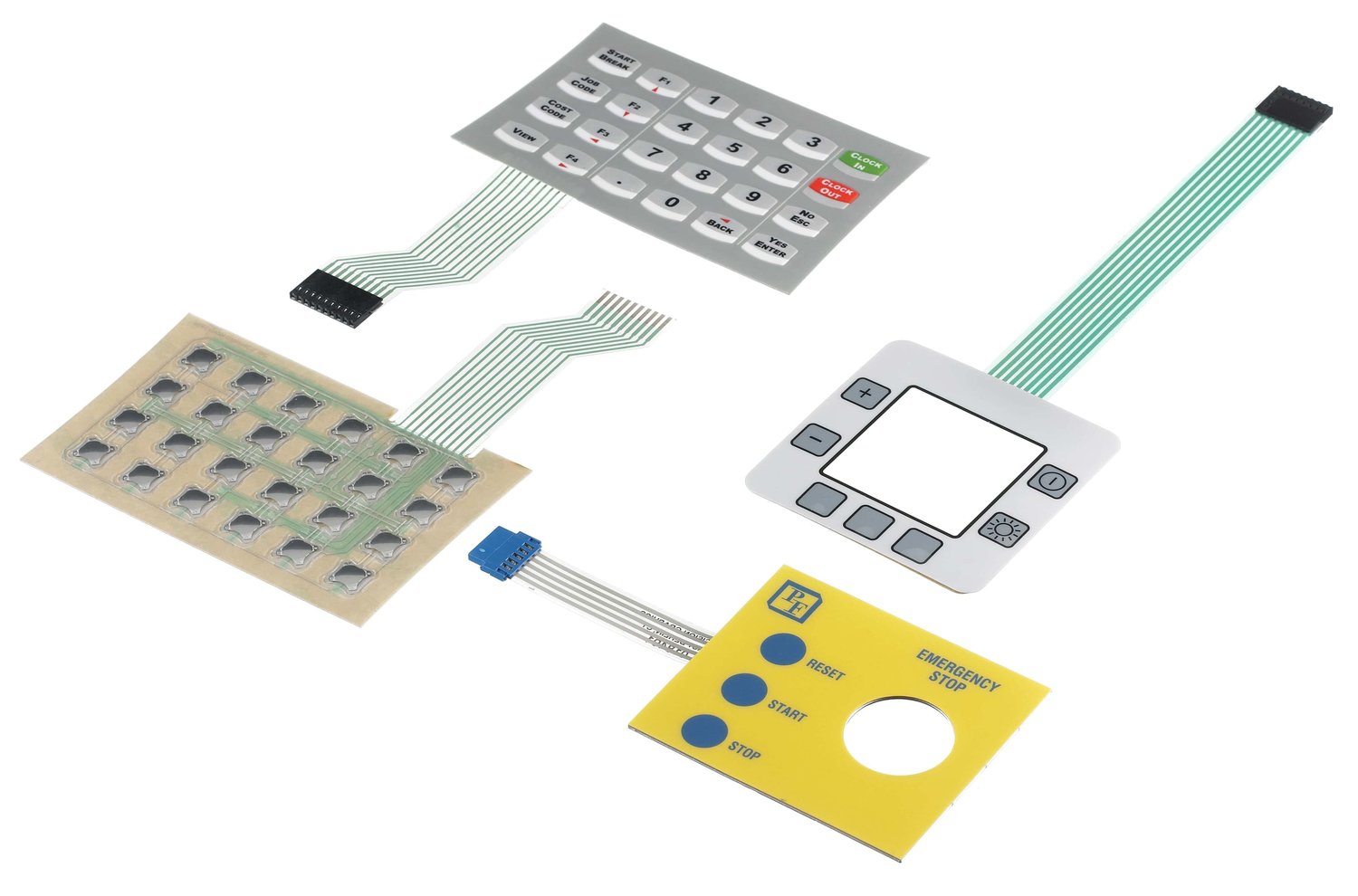

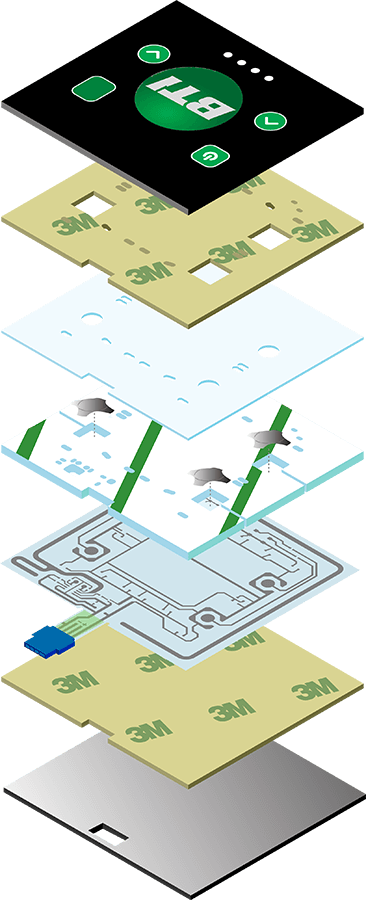

Ideal Jacobs is specialized in design support, quality and most importantly the cost control through years of support to elite customers. We further insert FPC into the membrane switches to help our customers enhance human-machine interfaces, to simply assembly with counterparts and to further improve the whole space of products especially for main PCB.

Flexible Printed Circuit largely improves the user experience and helps customer with more possibilities in product design by its compact size and light weight. It stretches freely in a three-dimensional space. Rigid-Flex PCB, on the other hand, can be an excellent support body of electronic components while being flexible.

Types of FPC:

1) Single Layer of FPC

It has a layer of chemically etched conductive pattern, and

the conductive pattern layer on the surface of the flexible insulating substrate

is a rolled copper foil.

2) Double-sided FPC

The double-sided FPC has a conductive pattern made by

etching on both sides of the insulating base film, which increases the wiring

density per unit area.

3) Multilayer FPC

Multi-layer FPC is to laminate 3 or more layers of single-sided

or double-sided flexible circuits together, and form metallized holes by

drilling and electroplating to form conductive paths between different layers.

4) Rigid-Flex PCB

it includes two or more conductive layers that comprise either

flexible or rigid insulation material between each one. Both rigid and flexible

areas that make them ideally suited for a wide range of applications.

Basic Specification:

No. | Item | Producing Capability |

1 | Layers | 1-6 |

2 | Panel Size | Max:500X550mm |

3 | Drilling Diameter | Min. Diameter: 0.15mm(6mil) |

4 | Base Material Copper Thickness | Min:1/3 Oz |

5 | Insulating Layer Thickness | Min:0.0125mm(PI)(0.5mIL) |

6 | Electroplating Au Thickness | ≥0.05um |

7 | Chemical Immersion Ni/Au Thickness | 0.05um---0.1um |

8 | Etching Line Width & Space | S/S:2mil(0.05mm) |

9 | Etching Tolerance | Width:±10% |

10 | Outline Tolerance(from side to side) | ±0.05mm(:±2mil) |

11 | Parts Fixed Position Tolerance | ±0. 2mm(8mil) |